Production

Cutting

Initial process to start production after raw material reception is cutting process.

Current facilities:

- 1 automatic shear line

- 3 automatic saw lines

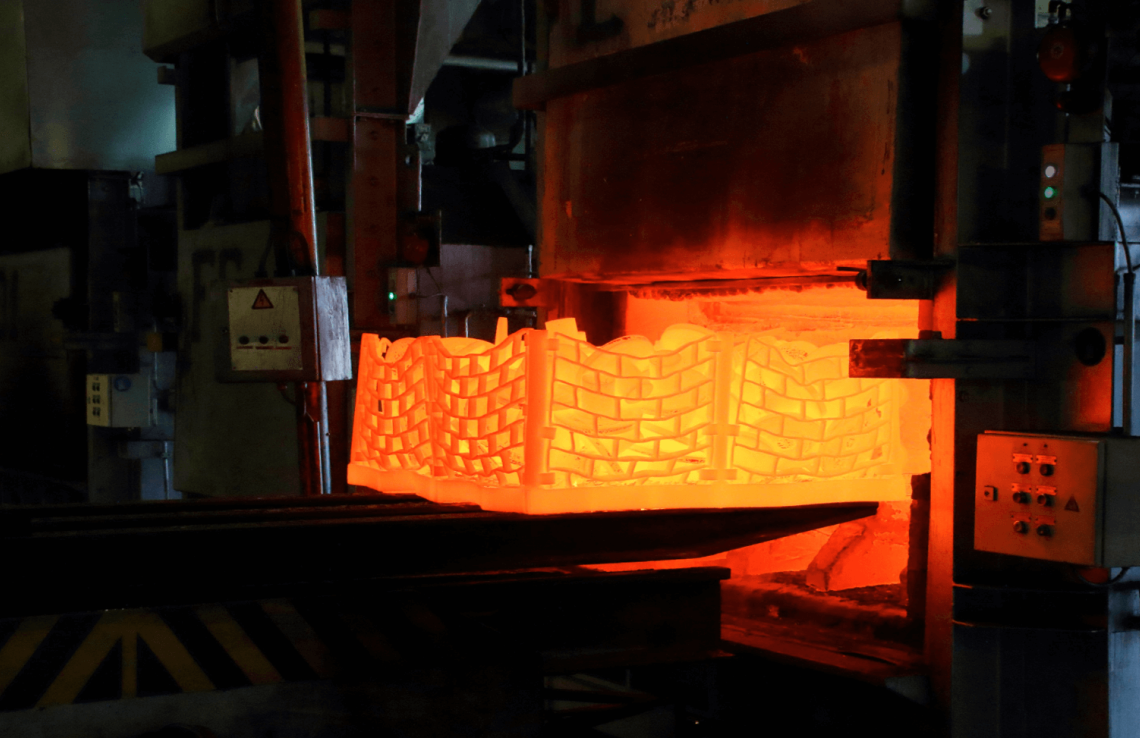

Forging

Forging is a primary metalworking process for producing a high volume complex configuration parts. Company has implemented hot and warm forging processes.

Available facilities:

Forging lines:

- 2 lines with 5000 t forging presses

- 2 lines with 2500 t forging presses

- 1 line with 2000 t forging press

- 2 lines with 1600 t forging presses

Other available facilities:

- 3 cold calibration presses

- 4 shot blasting facilities

- 2 manual crack control line

- 2 half automatic crack control lines

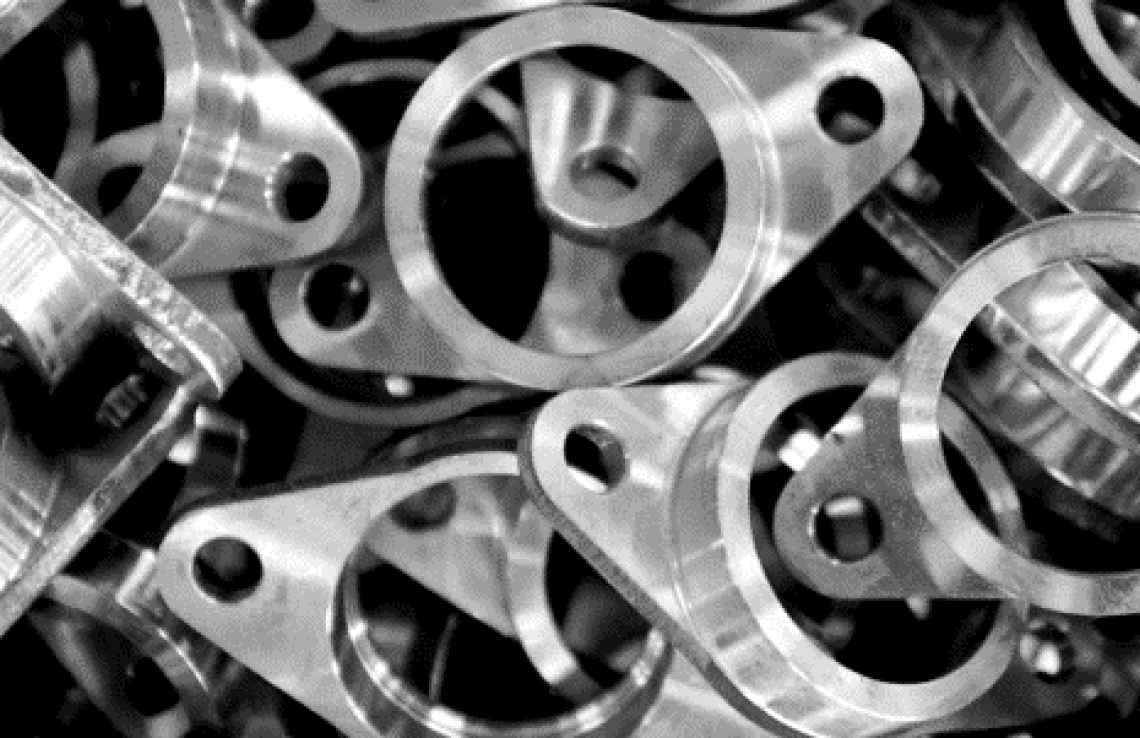

Machining

In company various machining processes are used: turning, drilling, milling and others. Parts can be premachined as well as final machined as well as final machined with high precision.

Available facilities:

- 12 Gildemeister CNC lathes

- 4 Mori Seiki high precision CNC lathes

- 1 tumbling machine

- 2 parts washing and canning lines

Heat treatment

For continuous process implementation after forging before machining there is heat treatment process. In company there is implemented following heat treatment processes: quenching, tempering, annealing, normalizing, stress relieving, induction hardening

Current facilities:

- 3 gas quenching ovens

- 3 gas annealing ovens

- 1 gas fast cooling oven

- 2 electrical annealing ovens

- 1 quenching tank

- 2 induction hardening facility

Tooling manufacturing

CIE LT Forge company is designing and manufacturing various tooling for forging and other own production needs.

Available facilities:

- 1 YCM CNC vertical milling machine

- 1 DMC 65 V CNC vertical milling machine

- 3 Deckel Maho CNC vertical milling machines

- 2 Gildemeister CNC turning machine

- 1 MoriSeiki CNC turning machine

- 1 Victor Vturn A-26 CNC turning machine

- 2 manual turning machines

- 1 manual milling machine

- 1 EDM wire cutting machine

- 2 EDM volume machines

- 1 EDM driling machine with wire

- 1 horizontal grinding machines

- 1 metal cutting machine

- 1 HT line

- 1 Rosler thumbling machine

- 1 manual drilling machine

- 1 nitrating bath

- 1 3D CMM Hexagon 8520 7AX